Textiles industry in India is one of the largest in the world with a huge raw material base and manufacturing strength across all value chains.The strength of India’s textiles industry lies both in the hand woven sector as well as mill sector. Traditional sectors like handloom, handicrafts and small scale power loom are the biggest source of employment for millions of people in rural and semi-urban areas. This industry contributes to 7% of industrial output in value terms, 2% of India’s GDP and 15% of the country’s export earnings.

“Today’s competitive world demands quick- time response in shaping initiatives to address the challenges of growth and converting them into opportunities. To this end, the Ministry of Textiles has been working relentlessly to ensure a conducive policy environment, facilitating enabling editions for the industry and private entrepreneurs to set up units through its various policy initiatives and schemes.”

SmritiZubinIrani

Union Minister of Textiles

|

“Ministry has formulated various measures to enhance the quality of Indian Textiles to international standards and to upgrade the skill of the workers.”

Ajay Tamta

Union Minister of State for Textiles

|

SILK INDUSTRY

Integrated Scheme for Development of Silk Industry:The Cabinet Committee on Economic Affairs approvedthe Central Sector Scheme "Integrated Scheme for Development of Silk Industry" for three years from 2017-18 to 2019-20. The Scheme has four components:

- Research & Development (R&D), training, transfer of technology and IT initiatives

- Seed organizations and farmers’ extension centres

- Coordination and market development for seed, yarn and silk products and

- Quality Certification System (QCS) by creating amongst others a chain of silk testing facilities, farm based & post-cocoon technology up-gradation, and export brand promotion.

The story of silk begins with cocoons

The scheme with atotal allocation of Rs.2161.68 crore is expected to increase the silk production from the level of 30348 MTs during 2016-17 to 38500 MTs by the end of 2019-20 with the following interventions:

• Production of import substitute bivoltine silk to the tune of 8500 MTs per annum by 2020.

• R&D to improve productivity from the present level of 100 Kgs to 111 kgs of silk per hectare of plantation by the end of 2019-20.

• Large scale propagation of improved reeling machines (automatic reeling machine for mulberry, improved reeling and spinning machineries and Buniyaad reeling machines for Vanya silk) under Make in India programme to produce quality silk to cater to the market demand.

The scheme will promote women empowerment and livelihood opportunities for SC and ST and other weaker sections of the society. It will help to increase productive employment from 85 lakhs to 1 crore persons by 2020.The scheme aims to achieve self-sufficiency in silk production by 2022. To achieve this, production of high grade silk in India will reach 20,650 MTs by 2022 from the current level of 11,326 MTs thereby reducing imports to Zero. It is proposed to increase 4A grade silk from the current level of 15% to 25 % of mulberry production by 2020. The implementation strategy is clearly based on convergence at the State level with the schemes of other Ministers like MGNREGS of Rural Development, RKVY & PMKSY of Ministry of Agriculture, for maximizing benefits to the sericulturists. The R&D projects pertaining to disease resistant silkworm, host plant improvements, productivity enhancing tools and implements for reeling and waving will be done in cooperation with Ministries of Science and Technology, Agriculture and Human Resource Development (HRD).

New Races of Silk Worm Seed:

Central Silk Board (CSB) has notified newly developed races of silkworm seed of mulberry and Vanya silk for increasing the productivity of cocoons and to increase the income of the farmers engaged in sericulture. Silk worm breeds for specific agro-climatic condition are essential for increasing the productivity of cocoons.

Tropical Tasar Silkworm (BDR-10)race developed have 21% more productivity than the traditional Daba breed. Farmers can get upto 52 kg cocoons per 100 disease free layings (dfls). Thissilkworm breed will help the tribal farmers of Jharkhand, Chattishgarh, Odisha, West Bengal, Andhra Pradesh, Maharastra, Madhya Pradesh, Bihar, Telangana and Uttar Pradesh.

Multivoltine x Bivoltine Mulberry hybrid(PM x FC2)race of silkworm can produce 60 kg per 100 Dfls and the race is better than earlier race PM x CSR. Due to high quality silk and significant egg recovery, this race is suitable for the farmers of Karnataka, Andhra Pradesh, Tamil Nadu, Telangana and Maharashtra.

Erisilkworm (C2)race can produce 247 numbers of Eri cocoons per 100 Dfls. This is suitable for the farmers in Arunachal Pradesh, Assam, Bihar, Maharastra, Madhya Pradesh, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Sikkim, Uttar Pradesh, Uttarakhand and West Bengal.

Central Silk Board under the Ministry of Textiles is engaged in applied research for developing new breeds of races of silkworm seed and conducts extensive field trial before commercial use in the field.

INTEGRATED SKILL DEVELOPMENT SCHEME (ISDS):

‘Samarth’- Scheme for Capacity Building in Textile Sector:

Union Minister of Textiles, SmritiZubinIrani, chaired a meeting of stakeholders on Samarth – Scheme for Capacity Building in Textile Sector under the Skill India Mission in May, 2018 in New Delhi, to familiarize the stakeholders about the scheme and its guidelines. The broad objective of the new scheme is to skill the youth for gainful and sustainable employment in the textiles sector covering the entire value chain of textiles, excluding spinning and weaving.

The concerns of the stakeholders and challenges faced by them during implementation of the previous scheme were discussed in the meeting. Feedback from the concerned stakeholders on how the scheme can contribute and benefit the textiles industry and boost skill development was also discussed.

The guidelines of the scheme were released on 23rd of April 2018. The scheme was approved by the Cabinet Committee on Economic Affairs on 20th of December 2017 with an outlay of Rs. 1300 crore. It is intended to provide demand driven, placement oriented National Skills Qualifications Framework (NSQF) compliant skilling programmes to incentivize and supplement the efforts of the industry in creating jobs in the textiles sector. The scheme targets to train 10 lakh persons (9 lakh in organised and 1 lakh in traditional sector) over a period of 3 years (2017-20).

The Integrated Skill Development Scheme (ISDS) was introduced by the Ministry of Textiles as a pilot scheme in the last two years of XI Five Year Plan (FYP) with an outlay of Rs. 272 crore, including Rs. 229 crore as Government contribution with a physical target to train 2.56 lakh persons. The scheme was scaled up as main phase during the XIIth FYP with an allocation of Rs. 1,900 crore to train 15 lakh persons. The ISDS addresses the critical gap of skilled manpower in textile industry through industry-oriented training programmes. It is implemented through three components where major thrust is given to PPP mode where a partnership has been developed with the industry in establishing a demand-driven skilling ecosystem. The scheme has been largely aligned with the common norms of Ministry of Skill Development & Entrepreneurship.

Skill Development in Textiles sector

- Total 11,14,545 persons were trained under the scheme mainly in apparel and garmenting (86%) with total expenditure of Rs. 935.17 crore, of which 8,43,082 persons (75.64%) were given employment in the textile sector.

- Out of the persons trained in last 4 years, more than 70% were women, 22.69% were from SC category and 7.22% were from ST Category.

Making a Difference Through Skilling:

- Textiles sectors employs over 45 million people.

- Additional requirement of about 17 million by the year 2022.

- In the last four years 8.58 lakh persons trained in partnership with 58 Government and industry partners.

- The Samarth guidelines have been issued on 23.04.2018 and RFP for empanelment of Implementing Partners has been floated on 21.05.2018.

HANDLOOM SECTOR

A weaver working at her loom

Block Level Clusters (BLCs):

Block Level Clusters (BLCs) are one of the components of National Handloom Development Programme (NHDP)/Comprehensive Handloom Cluster Development Scheme (CHCDS). 412 BLCs covering 3,18,347 beneficiaries have been sanctioned since July, 2015 with project cost of Rs. 557.59 crore.Rs. 212.77 crore has been released as Central share. Financial assistance is provided upto Rs.2.00 crore per cluster for various interventions like skill up-gradation, HathkarghaSamvardhanSahayata, product and design development, construction of workshed, lighting unit and setting up of Common Facility Centre (CFC).Besides, financial assistance upto Rs.50.00 lakh is available for setting up of one dye house at district level.

Weaver Mudra Scheme:

Under the Weaver Mudra Scheme, credit at concessional interest rate of 6% is being provided to the handloom weavers. Margin money assistance to a maximum of Rs. 10,000 per weaver and credit guarantee for a period of 3 years is also provided. 81,615 MUDRA loans worth Rs. 443.52 crore have been sanctioned under the scheme. MUDRA platform adopted in September, 2016 for providing concessional credit.Procedure for loan application on MUDRA platform is user friendly for withdrawal of loan amount using RuPay card through ATMs.

Handloom Weaver Mudra Portal:

This portal isoperation from 1stof April, 2017, in association with Punjab National Bank to cut down delays in disbursement of funds for financial assistance. Bank claims worth Rs. 25 crore have been settled through this portal. Participating banks submit the claim for margin money, interest subvention and credit guarantee fee on the portal and the margin money is transferred directly to loan account of the weaver and interest subvention and credit guarantee fee is transferred to banks in electronic mode.

India Handloom Brand:

Sales of handloom products to the tune of Rs.582.93 crore has been generated as on 31.10.2018. 1185 registrations have been issued under 122 product categories. The India Handloom Brand was launched by the Prime Minister on First National Handloom Day on 7th August 2015 for branding of high quality handloom products, authentic designs with zero defect and zero effect on environment.

BunkarMitra:

A toll free helpline no. 18002089988 was set up to deal with queries of handloom weavers. 22,033 queries of handloom weavers concerning wide range of issues like technical, supply of raw material, quality control, credit facility, access to market linkages were resolved upto 30.11.2018 through theBunkarMitra Helpline. The Helpline, set upin April 2017, provides single point contact to handloom weavers across the country for addressing their professional queries 7 days a week. Services are available through toll-free number in seven languages: Hindi, English, Tamil, Telugu, Bengali, Assamese and Kannada.

Common Service Centres (CSCs):

MoU was signed on 7th August 2017 with M/s CSC e- Governance Services India Limited to set up Common Service Centres (CSCs) to provide IT-enabled services, including e-commerce. Each CSC is set up @Rs. 3,78,400/- in handloom pockets, clusters and 28 Weavers’ Service Centres (WSCs). Of 162 CSCs sanctioned so far, 129 CSCs are functional.

Handlooms Promotion through e-Marketing:

To promote e-marketing of handloom products, 21 e-commerce entities have been engaged for on – line marketing of handloom products. So far, total sales of Rs. 21.25 crores have been generated.

To empower the weavers, and their families for career progression, memorandums of Understanding signed with Indira Gandhi National Open University (IGNOU) and National Institute of Open Schooling (NIOS). Ministry is providing reimbursement of 75% of the fee in NIOS/IGNOU courses for SC, ST, BPL and women learners.

POWERLOOM SECTOR

A comprehensive scheme for power loom sector development‘PowerTex’ India with an outlay of Rs.487.07 crore was launched all over the country in in January 2017. The component wise achievements till November2018 are:

- In-situ Upgradation of Plain Powerlooms: 197775 looms were upgraded and Rs.248.77 crores released.

- Group Workshed Scheme (GWS):1034 projects approved and Rs.85.64 crores released.

- Yarn Bank Scheme:73 Yarn Bank projects approved and Rs.23.263 crores released.

- Common Facility Centre (CFC):20 projects have been approved and Rs.3.944 crores released.

- Facilitation, IT, Awareness, Market Development and Publicity for PowerLoom Schemes: Rs.15.779 crores released.

- Tex Venture Capital Fund:Rs.9.34 crore has been disbursed by SVCL to four companies so far.

- Grant-in-Aid to Powerloom Service Centres:Rs.22.99 crores released.

- Modernisation of Powerloom Service Centres: Rs.3.39 crores released.

- A dedicated website www.ipowertexindia.gov.inhas been launched for applying various scheme under PowerTex India.

- Online portal and mobile app operational from 1.12.2017.

- Beneficiary can track the status online on Mobile app.

A worker operating the power loom

SCHEME FOR INTEGRATED TEXTILE PARK (SITP)

The scheme has been extended and notified for the period from 2017 to 2020.

- Total 65 textile parks.

- 20 new textile parks have been sanctioned in the last four yearsfrom 2014-18.

- These 20 parks will be facilitating investment up to Rs.6834 crores and generating employment for approximately 65,000 people.

- A total of 21 parks have been completed till date, out of which, 5 parks have been completed in the last four years (2014-18).

INTEGRATED PROCESSING DEVELOPMENT SCHEME (IPDS):

The scheme has been extended and notified for the period from 2017 to 2020.

- Six projects have been approved during the last 4 years, providing relief to about 1400 SME units and promoting ‘zero effect’ in textile processing.

TECHNOLOGY UPGRADATION FUND SCHEME (TUFS)

Amended TUFS (ATUFS) launched for the period of 2016-2022

- Outlay Rs 17,822 crore including committed liabilities of previous schemes

- Guidelines modified on 02.08.2018 to make I-TUFS an end to end solution

AMENDED TECHNOLOGY UPGRADATION FUND SCHEME (ATUFS)

- 6,468 UIDs issued under ATUFS.

- Projected investment- Rs. 24,338.75 crores.

- Projected Subsidy value Rs.1,795.50 crores.

- Total subsidy released Rs. 8156 crores.

HANDICRAFT SECTOR

Pehchan cards being distributed to weavers in Madhya Pradesh

Pehchan cards being distributed to weavers in Madhya Pradesh

‘Under Pehchan’ initiative,22.40 lakhs applications were received and 17.83 lakhs I.D. cards have been distributed. This initiative was launched on 7th October, 2016 to register and provide Aadhar based Identity Cards to the Handicrafts Artisans for better access to the benefits of the schemes. New Mega Clusters have been sanctioned at Bareilly, Lucknow and Kutch with an outlay of Rs. 28.5 crores each and at J&K with an outlay of Rs. 20.00 crores and activities underway.

- In the project of linking Textiles with Tourism, Raghurajpur in Odisha and Tirupati in Andhra Pradesh were taken up for overall development as tourist destinations.

- Special projects have been sanctioned for Integrated Development and Promotion of Handicrafts in Jharkhand, Uttarakhand, Kerala, Madhya Pradesh, Tamil Nadu, Andhra Pradesh, Telangana, Karnataka, Bihar, Varanasi (Uttar Pradesh) to benefit 1,58,805 artisans.

- New Urban Haats sanctioned at a project cost of Rs. 3.00 crores each, atMammallapuram(Chennai) and Eluru (Andhra Pradesh).

Programmes Conducted and Artisans Benefitted during Last Four and Half Years:

- AmbedkarHastshilpVikasYojana: 435 programme organized amounting to Rs 58.40 Crores benefiting 306583 artisans.

- Design and Technology Upgradation: 756 programme organized amounting to Rs. 53.33 Crores benefiting 29570 artisans.

- Marketing Support and Services: 788 programme organized amounting to Rs 87.61 Crores benefiting 58526 artisans.

- Human Resource Development: 2182 Training programme organized amounting to Rs 93.07 Crores benefiting 46481 artisans.

- Research and Development: 702 programme organized amounting to Rs 23.39 Crores benefiting 17550 artisans.

- Direct Benefit to Artisans: Rs 58.40 Crores sanctioned benefiting 478089 artisans.

- Infrastructure & TechnologySupport: Rs 98.76 Crores sanctioned to provide infrastructural support.

- Comprehensive Handicrafts Cluster Development (Mega Cluster): Rs. 226.65 Crores sanctioned benefiting 71915 artisans.

- HastkalaSahyogShivirs organized at 302 places all over the country, in which 73291 artisans participated. 5155 tool kits distributed, 814

- Mudra Loan sanctioned, 695 marketing events were organized during the camp during the financial year 2017-18.

- Handicrafts Awards to 23 Shilp Gurus and 65 National Awardees (including 15 Women artisans) have been given to Handicraft artisans since 2014 to 2016.

- The new component of Margin Money has been approved in the month of October 2018, introduced for implementation for the benefit of artisans availing Mudra Loan @ 20% of the sanctioned loan amount subject to a maximum of Rs.10,000.

Promotion of Handcrafts:

To celebrate birth anniversaries of Baba SahebBhimraoAmbedkar and Mahatma JyotiraoGovindroPhule, 24 marketing events were organized for SC/ST artisans from11th to 17th April 2018 in different parts of the country benefitting approximately 1000 SC/ST artisans

Artisans making handcrafted items

Promotion of Carpet weaving:

Carpet weaving in Kashmir

Cluster – based approach – training is organized for 4 months in traditional carpet weaving belts such as Uttar Pradesh and Kashmir.

Common Facility Centre with warehouses for storing raw material, office with internet facilities, restroom and training shed at a cost of about Rs. 50 lakh for a group of artisans.

The Carpets Export Promotion Council is implementing this with the help of the National Centre for Design and Product Development (NCDPD), New Delhi.

Export of Handicraft Products:

- Export of handicraft products increased from Rs.20082.54 crores in 2014-15 to Rs 22916 crores in 2017-18.

- Exports of carpet increased from Rs 8441.95 crores in 2014-15 to Rs. 9205.90 crores in 2017-18.

VISA EXEMPTION TO FOREIGN DESIGNERS IN HANDICRAFTS SECTOR

Handicrafts sector has been exempted from minimum salary condition (Rs. 16.25 lakhs per annum) for grant of employment visa to foreign designers for a period of 2 years i.e. till 30.06.2020. Export Promotion Council for Handicrafts (EPCH) had sought the intervention of Union Minister of Textiles for getting the exemption from the minimum salary condition for grant of employment visa to foreign designers. The Textiles Minister’s prompt action to obtain the exemption for handicrafts sector will help the exporters to hire international designers as per their requirement and develop products in sync with international trends.

COTTON

MSP Operation of Seed Cotton (Kapas)

To ensure remunerative prices to cotton farmers, Government fixes Minimum Support Prices (MSPs) of seed cotton (kapas) every year.

Minimum Support Price (MSP) of cotton for Crop Season 2018-19 has been increased by Rs. 1,130/- per quintal over last year.

Cotton Corporation of India (CCI) is the Central Nodal Agency for undertaking Price Support Operations of Cotton.

CCI undertakes MSP Operation when market rate of seed cotton falls below the MSP rates.

COTTON CORPORATION OF INDIA (CCI)

CCI has put in place many innovative measures:

- Adopted ERP system ‘PRAGTI’ to enabled the CCI with fast access of all the important information of its branches and corporate office.

- Developed computer based programme for identification of cotton farmers.

- Initiated 100% online payment directly in the account of cotton farmers to ensure the full benefit of MSP and to avoid middlemen.

- Developed farmer friendly mobile app ‘Cott-Ally’ to keep the cotton farmer informed about policy initiatives in respect of cotton and steps taken by CCI for implementation of MSP.

- CCI commenced the 100% sales of Lint cotton bales and cotton seed through online e-auction system.

- Developed warehouse management system for online stock management.

- Started monitoring the branch operations/meeting with the branch heads through video conferencing in order to save time and money.

- Adopted 100% cashless transactions.

Revival of National Textile Corporation (NTC):

With net worth turning positive, NTC ceased to be a sick company and came out of the purview of Board for Industrial and Financial Reconstruction (BIFR). As on 31st March 2018 its net worth stood at Rs. 1,885.87 crore.

Promotion of Wool Sector:

Pashmina shawl from Kashmir

- A total grant of Rs.41.47 crore released under Pashmina Scheme for 4 years. (2014-15 to 2017-18)

- Foundation stock of animals distributed to 340 families in Leh and Kargil.

- Distributed 459 high quality Pashmina bucks for breed improvement.

- Health coverage and medicines to 2 lakh Pashmina goats annually and feed supplement was given to 40,000 goats annually.

- Strengthened 3 breeding farms & 3 fodder banks and established 3 pasture farms on migratory routes.

- Pashmina productivity per goat enhanced by 9.30%.

- Provided 775 tents and 100 houses for nomads in Ladakh region.

- Five solarized community centres constructed.

- Benefitted 40 lakh sheep under ‘Sheep & Wool Improvement Scheme’ (SWIS) under “Health Care” to animals.

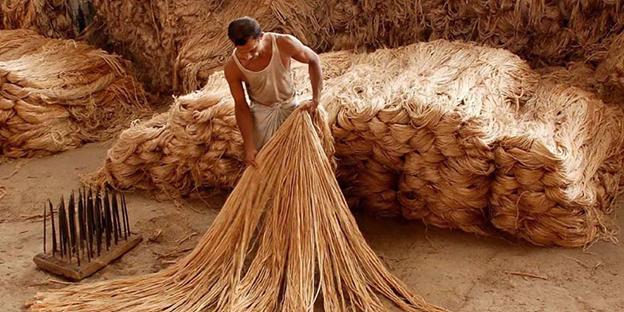

JUTE SECTOR

Bundles of Jute Fiber in a jute mill

The Ministry has launched “Scheme for Research and Development for the Textile Industry including Jute” for a period of five year from 2014-15 to 2018-19 with a financial outlay of Rs. 149 Crore. The Scheme has three basic components:

- Component - I : Research and Development in Textiles and allied Sector (Financial Outlay Rs. 50 Crore)

- Component – II : Promotion of R&D in Jute Sector; Transfer of technologies and dissemination activities in jute sector (Financial Outlay : Rs. 80 Crore)

- Component – III : Benchmarking studies, Knowledge dissemination and promoting green initiatives through R&D (Financial Outlay: Rs. 15 Crore)

Financial support : In case of any of the above 3 components, for applied Research, the Scheme has provision of funding upto 70% of the total project cost and balance would have to be arranged by the respective Project Executing Agency. Similarly, for basic research, 100% funding shall be provided under the Scheme.

Extension of Norms for Mandatory Packaging in Jute Materials:

The Cabinet Committee on Economic Affairs accorded its approval to expand the scope of mandatory packaging norms under the Jute Packaging Material (JPM) Act, 1987 as follows:

- 100% of the food grains and 20% of the sugar will be mandatorily packed in diversified jute bags. The decision to pack sugar in diversified jute bags will give an impetus to the diversification of the jute industry.

- Initially 10% of the indents of jute bags for packing foodgrains will be placed through reverse auction on the GeM portal. This will gradually usher in a regime of price discovery.

- The decision will give a fillip to the development of jute sector in increasing the quality and productivity of raw jute, diversification of jute sector and also boosting and sustaining demand for jute product.

- The jute industry is predominantly dependent on Government sector which purchases jute bags of value of more than Rs. 6,500 crore every year for packing foodgrains. This is done in order to sustain the core demand for the jute sector and to support the livelihood of the workers and farmers dependent on the sector.

- The decision will benefit farmers and workers located in the Eastern and North Eastern regions of the country particularly in the states of West Bengal, Bihar, Odisha, Assam, Andhra Pradesh, Meghalaya and Tripura. Nearly 3.7 lakh workers and several lakh farm families are dependent for their livelihood on the jute sector.

Government support to the Jute Sector:

- In order to improve the productivity and quality of raw jute through a carefully designed intervention, called the Jute ICARE, the Government has been supporting close to one lakh jute farmers by disseminating improved agronomic practices such as line sowing using seed drills, weed management by using wheel-hoeing and nail-weeders, distribution of quality certified seeds and also providing microbial assisted retting. These interventions have resulted in enhancing the quality and productivity of raw jute and increasing income of jute farmers by Rs. 10,000 per hectare.

- To support jute farmers, Jute Corporation of India (JCI) has been given a grant of Rs. 100 crore for 2 years starting from 2018-19 to enable it to conduct MSP operations and ensure price stabilization in the jute sector.

- The National Jute Board has collaborated with National Institute of Design to support diversification of jute sector and a Jute Design Cell has been opened at Gandhinagar. Further, promotion of Jute Geo Textiles and Agro-Textiles has been taken up with the State Governments particularly those in the North Eastern region and also with departments such as Ministry of Road Transport and Ministry of Water Resources.

- With a view to boost demand in the jute sector, Government of India has imposed Definitive Anti-Dumping Duty on import of jute goods from Bangladesh and Nepal with effect from 5th January, 2017. As a result of these measures, 13 Twine mills in Andhra Pradesh have resumed operation, benefitting 20,000 workers. Further, imposition of Definitive Anti-Dumping Duty has provided scope for an additional demand of 2 lakh MT of jute goods in the domestic market for the Indian jute industry.

- With a view to promoting transparency in jute sector, Jute SMART, an e-govt initiative was launched in December, 2016, providing an integrated platform for procurement of B-Twill sacking by Government agencies. Further, the JCI is transferring 100% funds to jute farmers online for jute procurement under MSP and commercial operations.

TECHNICAL TEXTILES

Technical textiles are textile material and products manufactured primarily for technical performance and functional properties rather than aesthetic and decorative characteristics. They find application not only in clothing but also in areas like agriculture, medical, infrastructure, automotive, aerospace, sports, defence and packaging. Scheme for promoting usage of geotechnical textiles in NER with fund outlay of Rs. 427 crore was launched for the Financial Years 2014-15 to 2018-19

- 54 projects sanctioned under geotech textiles with an outlay of more than Rs. 105 crores providing quality infrastructure like roads, hill slope protection and efficient water usage by water reservoir lining.

- Eight centres of excellence, 11 focus incubation centres, sanctioned, 10 agro-demo centres set up and 200 agro kits distributed in 6 states with an outlay of Rs. 208 crores since 2012-13 till 2016-17 under technology mission on technical textiles.

- Under the scheme for promotion of usage of agro textiles, 44 demonstration centres set up, 840 agrotextile kits were distributed to agro farmers after training about 3841 farmers.

- 118 projects under scheme for research and development for the textiles industry including jute with a total project cost of Rs. 11,042.86 lakhs and Government of India share of Rs. 7,851.86 lakh are being supported for development and better quality textile product.

- Technotex, India’s premier show on technical textiles was organized in association with FICCI to provide boost to Technical Textiles in 2014, 2015, 2016 and 2017.

NORTH EAST REGION TEXTILE PROMOTION SCHEME (NERTPS)

This scheme promotes textiles industry in the North Eastern Region by providing infrastructure, capacity building and marketing support to all segments of textile industry. The scheme has an outlay of Rs. 500 crores during 2017-18 to 2019-20.

Woman weaving shawl in Nagaland

Under North East Region Textile Promotion Scheme (NERTPS), 32 sericulture projects are being implemented viz., Integrated Sericulture Development Project (ISDP) and Intensive Bivoltine Sericulture Development Project (IBSDP) covering Mulberry, Eri and Muga sectors in all North East States. The projects aim at holistic development of sericulture in all its spheres from plantation development to production of fabrics with value addition at every stage of production chain.

NATIONAL INSTITUTE OF FASHION TECHNOLOGY (NIFT)

NIFT students receiving certificates from Textiles Minister

Indiasize, a National Sizing Survey will be conducted by the National Institute of Fashion Technology(NIFT), New Delhi, to develop a comprehensive size chart for ready-to-wear industry based on the body measurements of the Indian population. It is a scientific exercise where anthropometric data will be collected from a sample population in the age group 15 to 65 years to create a database of measurements that will result in a standardized size chart which is representative of the Indian population and can be adopted by the apparel industry. The surveys entail measuring statistically relevant sample size pan country using human safe technology of 3D whole body scanner, a non-contact method of taking body measurements and analyzing the collected data to create size charts.

The project will entail measuring of 25,000 male and female Indians in 6 cities in 6 regions of the country: Kolkata(East), Mumbai(West), New Delhi(North), Hyderabad(Central India), Bengaluru(South) and Shillong (North-East). Using 3D whole body scanners, computers will extract hundreds of measurements from a scan. The data created as part of this project will be confidential and secure. The duration of the project will be around two years from the date of commencement.

Providing well-fitting garments in the absence of standardized size chart is proving to be a big challenge for the domestic textile and apparel industry which is projected to reach USD 123 billion by 2021 and holds 5th position in apparel imports.

A large percentage of shoppers face difficulty in finding clothes that fit perfectly according to their body measurements. The reason is differences in anthropometric built of people in different geographical regions across the country. Till date 14 countries have successfully completed national sizing surveys: USA, Canada, Mexico, UK, France, Spain, Germany, Korea, China and Australia.

Indian apparel industry uses size charts which are tweaked versions of size charts of other countries so returns of the garments are in the range of 20% to 40% and is increasing with the growth of ecommerce and the main reason for returns are poor garment fit.

The findings of the study will impact various other sectors like automotive, aerospace, fitness and sport, art and computer gaming where insights from this data can produce ergonomically designed products which are suited for the Indian population.

Capacity Building in Fashion Technology:

- The NIFT International Conference based on the theme Rediscovering Culture: Transforming Fashion was held in New Delhi from 31st January to 2nd February 2018 as a milestone in its thirty - year journey.

- The conference provided an interdisciplinary platform for trans – global narratives on fashion, culture, textiles, craft and sustainability.

- A NIFT campus at Srinagar (J&K) opened at a project cost of Rs. 325.36 crore. Foundation stone of a NIFT campus at Panchkula laid. The institute infrastructure such as academic blocks, administrative blocks, hostels and student centres being augmented at various campuses.

- NIFT signed MoUs with DC (Handicraft) and DC (Handlooms) for “Cluster Initiatives for symbiotic collaboration in linking handloom clusters with budding fashion professionals.

- Extension centre of NIFT set up at Varanasi to train & encourage wavers to revive traditional designs.

- USTAAD (Upgradation of Skills and Training in Ancestral Arts/Crafts for Development) project initiated in collaboration with Ministry of Minority Affairs – will encompass 25 handicraft and handloom clusters.

- Set up a Product Design Development & Innovation Centre under Comprehensive Handicrafts Cluster Scheme for Jodhpur Mega Cluster (Handcrafts)

- Four one – year Certificate Programmes introduced in Fashion Design Development (CPFDD), Fashion Design and Management (CPFDM), Application of Information Technology in Fashion (CPAIT) and Knitwear Design and Manufacturing (CPKDM) for Ministry of DONER.

- Designing of uniform for postal employees, trainees and staff of CITs & CTS.

EXPORT PROMOTION INITIATIVES

To enhance exports of textiles including woolen, silk and cellulose fibers from India, the Government has enhanced rates under Merchandise Exports from India Scheme (MEIS) from 2% to 4% for apparel, 5% to 7% for made-ups, handloom and handicrafts from 1st November 2017. Further, the Government has enhanced interest equalization rate for pre and post-shipment credit for the textile sector from 3% to 5% from 2nd November, 2018. For the silk sector, Government has introduced Silk Samagra Scheme to promote R&D and brand image of Indian silk at the global level and provide support to beneficiaries from nursery to fabric production stage for improvement in productivity and quality.

PACKAGE FOR TEXTILES, APPARELS AND MADE UPS

Special Package

Package was designed to create upto one crore jobs, and boost exports (by USD 31 billion) and investment by Rs. 80, 000 crores in 3 years. As on date it has generated potential for 15.68 lakh additional employment with additional exports of Rs. 5,728 crores and additional investments Rs. 25,345 crores.

- A special package of Rs. 6000 crore was announced in June and December 2016 to boost exports, attract investments and create employment opportunities

- Entire 12% of employer’s Employees Provident Fund (EPF) contribution for apparel and made-ups is borne by Government under Pradhan MantriParidhanRozgarProtsahanYojana (PMPRPY).

- Fixed Term Employment for apparel sectorintroduced making fixed term workman at par with permanent workman in terms of working hours, wages, allowances and other statutory dues.

- Outcome oriented Capital Investment subsidy under ATUFS for apparel and made-ups sector enhanced by 10%

- Rs. 4,853.6 crore Rebate of State Levies (RoSL) disbursed to exporters as on 15th November, 2018. Rebate of State Levies (RoSL) schemewasannounced as part of special package for apparel and made-ups.

To boost indigenous production and Make in India, Government has increased Basic Customs Duty from 10% to 20% on 501 textile products.

Strategy to boost exports:

It involves diversification of markets, positioning India in value chain and promoting collaborative exports.

- Diversify Markets: 12 markets in Vietnam, Indonesia, South Korea, Australia, Egypt, turkey, Saudi Arabia, Russia, Brazil, Chile, Columbia and Peru have been identified.

- Position India in Value Chains: Pursue strategic engagement with Bangladesh and Sri Lanka: Fabric-Forward Policy

- Promote Collaborative exports:

- Apparel and Contract textiles

- Attract investment in textile parks

- Export traditional garments under G2G initiative

- Diversify products:

- Integrate Indian fabrics into demand for contract textiles

- Supply jute bags Latin American Country (LAC) retailers

- Create digital platform for Latin for (LAC) countries

- Launch National Textiles Mission on Quality and Compliance

- Strengthen quality and compliance mechanism

- Develop quality ecosystems @ Rs. 100 crore upto 31.3.2020

- Establish warehouses cum display centres: China (Shanghai), Russia (Moscow), LAC

(1 in Panama for Columbia and Peru and 1 in Chile) and Saudi Arabia

- Boost exports through cross-border e-commerce provider

***

MM/ SB

(Release ID :186673)